Our Services

Process and Best Practices

At THINK Inventory Solutions, we are committed to providing comprehensive support and expert guidance throughout your Warehouse Management System (WMS) journey. Our wide range of services is designed to ensure your success, from initial implementation to ongoing optimisation.

Process and Best Practices

Stay ahead of industry trends with our process and best practices consulting. We help you refine your warehouse operations by identifying inefficiencies and recommending proven strategies. Our experts provide actionable insights and hands-on support to help you implement these practices, ensuring your operations are optimised for maximum performance.

Benefits of Process and Best Practices

- Streamlined workflows to optimise picking, packing, and shipping processes.

- Best practices for maintaining real-time inventory accuracy and reducing discrepancies.

- Efficient space utilisation strategies for maximising warehouse capacity.

- Implementing automated processes to minimise manual tasks and errors.

- FIFO, LIFO, and FEFO inventory rotation practices for effective stock management.

- Regular cycle counting to ensure inventory levels are accurate and up to date.

- Optimising labour management by assigning tasks based on skill level and efficiency.

- Continuous performance monitoring by providing data through reports and exports to support customer KPIs.

- Best practices for integrating WMS with other business systems (ERP, TMS, eCommerce platforms).

- Adapting inventory management workflows to support future growth and operational changes.

Why Choose think?

We employ experienced WMS consultants to work with your company and assess the current warehouse operations, understand your specific needs and challenges, and then recommend, implement, and customise WMS solutions that align with the company’s goals and objectives. Our expertise covers a wide range of areas, including technology, logistics, supply chain management, process optimisation and software integration. When combined with our approach to project management, this leads to consistent achievement of objectives within agreed timescales.

From the outset our Warehouse Management System was designed to easily interface with other business applications ranging from ERP systems such as SAP, System 21, SAGE, MS Dynamics, Oracle etc. Through to Ecommerce providers such as Shopify and Prestashop.

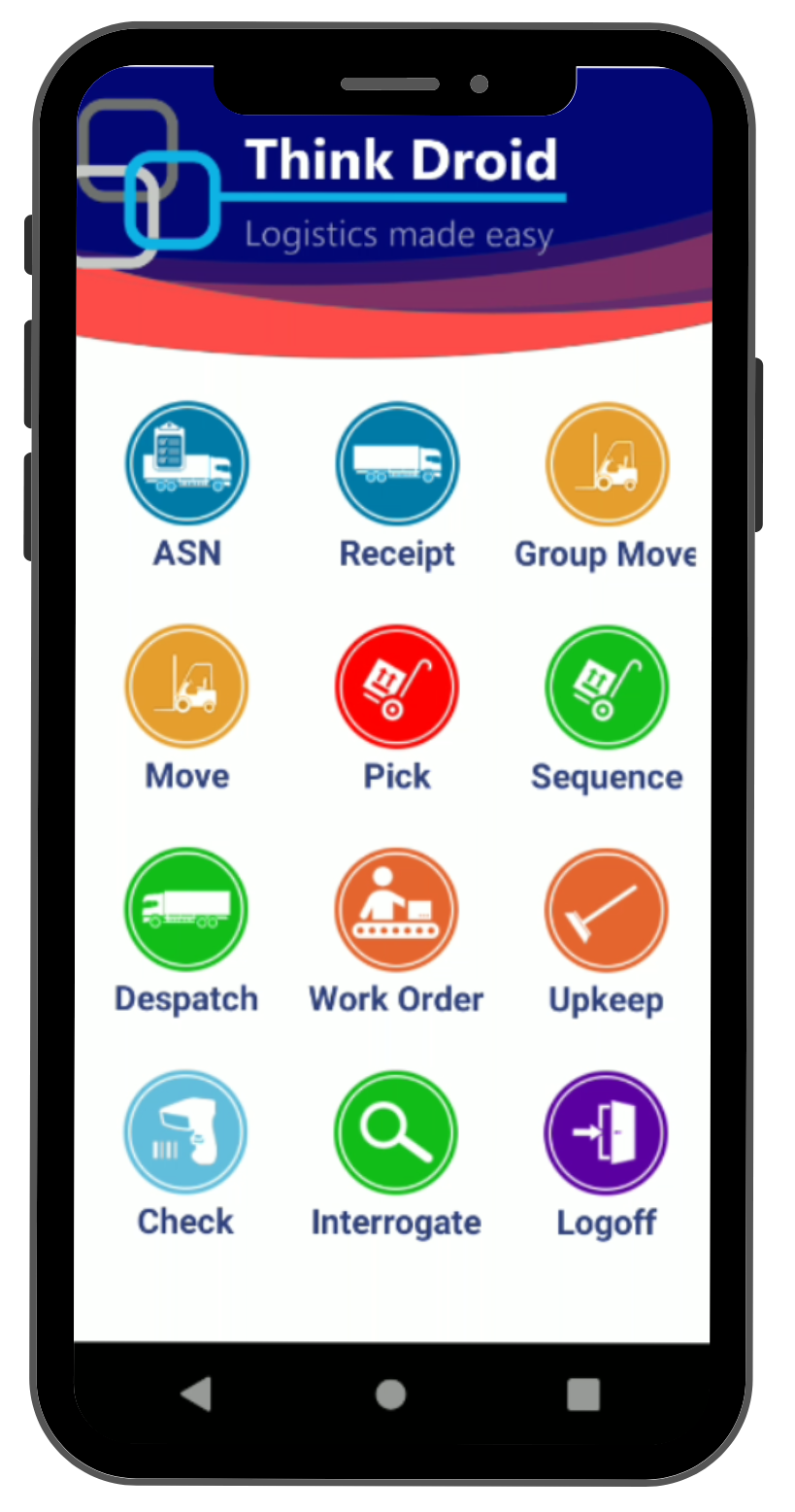

Implementing a warehouse management system / WMS should not mean an upheaval on time or costs. THINK’s wealth of industry experience with a deep routed industry skill set means we can work with your business to provide the most intuitive WMS on the market. Get your staff trained and operational within 45 minutes – it really is that user friendly.

Here is an example of our system on an Android phone, showing how you can use it on the go.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements, give THINK a call on 0330 350 0715, email enquiries@tkinv.com or complete the Quick Quote form below. We can work with your business to help save you money and drive down costs.

REQUEST A QUICK QUOTE

WAREHOUSE MANAGEMENT SYSTEM PRODUCTS

You may also be interested in the following products:

INBOUND

The ability to start the inventory management process at the point of receipt. Read more about our Inbound Warehouse Management System.

LOCATE & MANAGE

Inbound stock control is a critical aspect of warehouse management that focuses on effectively managing and controlling inventory as it arrives at the warehouse, whilst ensuring efficient utilisation of available space. Read more about Locate & Manage Stock Management.

DEMAND FULFILLMENT

THINK’s warehouse management system fulfils customer orders efficiently and accurately based on demand signals received by the WMS. Read more about our Demand Fulfillment Functionality.

OUTBOUND

We help you provide your customers with real-time information on their shipments at the point of despatch. Read more about our Outbound Functionality.

CORE

THINK WMS provides full traceability for all transactions at handling unit level. Read more about our Core Functionality.