In today’s rapidly evolving logistics environment, integrating artificial intelligence (AI) into warehouse management systems (WMS) is revolutionising the way warehouses operate. By leveraging the power of AI, warehouses can achieve unprecedented levels of efficiency, accuracy, and flexibility. In this blog, we explore how AI is being used in WMS and the transformative benefits it brings to the warehousing and distribution industry.

Predictive Analytics for Inventory Management

AI-powered predictive analytics is a game changer for inventory management. By analysing historical data and recognising patterns, AI can predict future inventory needs with high accuracy. This helps to:

- Demand forecasting: AI algorithms predict fluctuations in demand, ensuring optimal inventory levels and reducing the risk of stockouts and overstocks.

- Automated replenishment: Automatic reorder triggers based on predictive analytics ensure timely replenishment, improving inventory turns and reducing storage costs.

Improve Order Picking Efficiency

Order picking is one of the most labour-intensive tasks in a warehouse. AI optimises this process by:

- Intelligent route planning: An AI-powered warehouse management system determines the most efficient picking route, minimising travel time in the warehouse and speeding up order fulfilment.

- Voice-controlled picking: An AI-powered voice recognition system guides employees through the picking process, improving accuracy and reducing the time it takes to find items.

Warehouse Layout Optimisation

AI algorithms analyse warehouse operations and suggest optimal layouts for storage and movement. This includes:

- Dynamic scheduling: AI adjusts item placement based on demand and picking frequency, making fast-moving items easier to access.

- Space Utilisation: By analysing inventory data, AI helps to use storage space more effectively, reducing wasted space and improving overall efficiency.

Real-time Inventory Tracking and Management

AI improves real-time inventory tracking through advanced technology.

- Computer Vision: AI-powered cameras and sensors continuously monitor inventory and provide real-time updates and alerts in case of deviations.

- IoT Integration: Combining AI with the Internet of Things (IoT) enables real-time tracking of goods through sensors and RFID tags, ensuring accurate inventory records.

Improve Accuracy and Reduce Errors

AI significantly reduces errors in warehouse operations by automating data entry and validation processes. This includes:

- Automatic data capture: AI-integrated barcode scanners and RFID readers automate inventory data entry, minimising manual errors.

- Quality control: AI systems detect anomalies in order processing and stock levels, quickly identifying and correcting errors.

Improve Decision-making Through Data Insights

AI provides deep insights into warehouse operations, enabling informed decision-making.

- Operational insights: AI analyses large volumes of data to identify inefficiencies and areas for improvement, enabling managers to make data-driven decisions.

- Performance Metrics: Real-time tracking of key performance indicators (KPIs) through AI-powered dashboards allows for continuous monitoring and optimisation.

Optimising Supply Chain Management

AI doesn’t just benefit warehouses; it improves overall supply chain management.

- Supplier Management: AI can evaluate supplier performance, forecast delivery times, and suggest optimal sourcing strategies.

- Demand Planning: AI-powered demand planning aligns supply chain operations with market demand, reducing stockouts and improving responsiveness.

Fostering Robotics and Automation

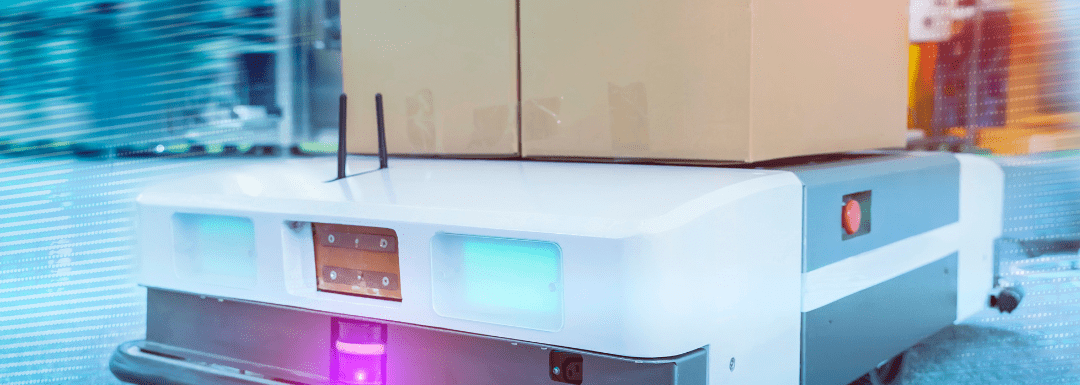

AI is the foundation for integrating robotics and automation in warehouses.

- Automated Guided Vehicles (AGVs): AI controls AGVs for material handling, reducing the need for manual labour and improving efficiency.

- Robotic Order Picking Systems: AI-powered robots can accurately select and pack goods, significantly speeding up order fulfilment and reducing human error.

The integration of AI into warehouse management systems is transforming the warehousing and distribution industry. With AI, businesses can optimise inventory management, increase picking efficiency, improve accuracy, and make data-driven decisions. As AI technology continues to develop, AI applications in WMS will continue to increase, driving further innovation and efficiency in warehouse operations.

Are you worried that a warehouse management solution will be too expensive, or that you will be trapped in a long contract? To arrange a demo or discuss your requirements, give THINK a call on 0330 350 0715, email enquiries@tkinv.com or complete the Quick Quote form below. We can work with your business to help save you money and drive down costs.

Recent Comments